Equipment needed to produce nitrogen / oxygen from compressed air

Tags

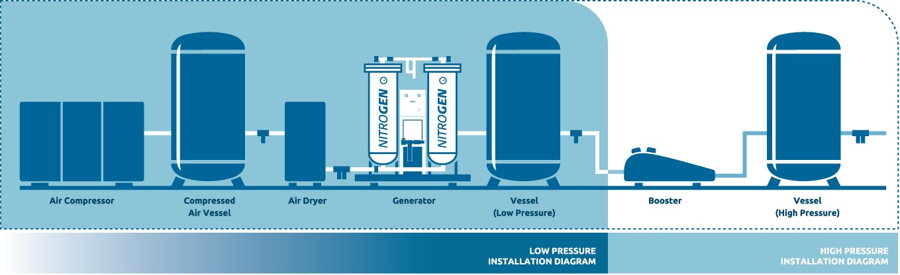

The actual nitrogen production is based on the separation of nitrogen from compressed air. Compressed air is produced by a common air compressor and before entering the generator it is adjusted to the appropriate quality, which must meet the requirements of the ČSN EN 8573-1 standard, class 1-4-1. For this reason, the necessary air conditioning devices are located behind the compressor. The compressed air is dehumidified using a cyclone separator and a condensing dryer with a dew point of + 3 degrees Celsius. The air also passes through a filtration system where it is freed of solid impurities and oil through a pre-filter to 0.1 micrometre, further filtered by a microfilter which removes fine impurities and residual oil from the air to 0.001 micrometre and finally filtered through an activated carbon column to remove oil. vapors and aerosols with a maximum residual content of less than 0.003 mg / m3. Behind the activated carbon column, dust filters are located to filter the activated carbon dust. The condensate generated during the air production process is discharged from the system using a condensate drain and is ecologically divided into oil and water in a separator. The nitrogen separation process itself takes place in a nitrogen generator, which works on the principle of alternating pressure adsorption of PSA and separates nitrogen from the air with the required purity of up to 99.999%. The nitrogen produced by the generator is further fed to a process vessel for backfilling with nitrogen. At the outlet, it is freed of small impurities by means of a microfilter, which can ignite in the pipeline.